Wholesale Silicone Tail Plug Manufacturer | ODM & Factories Available

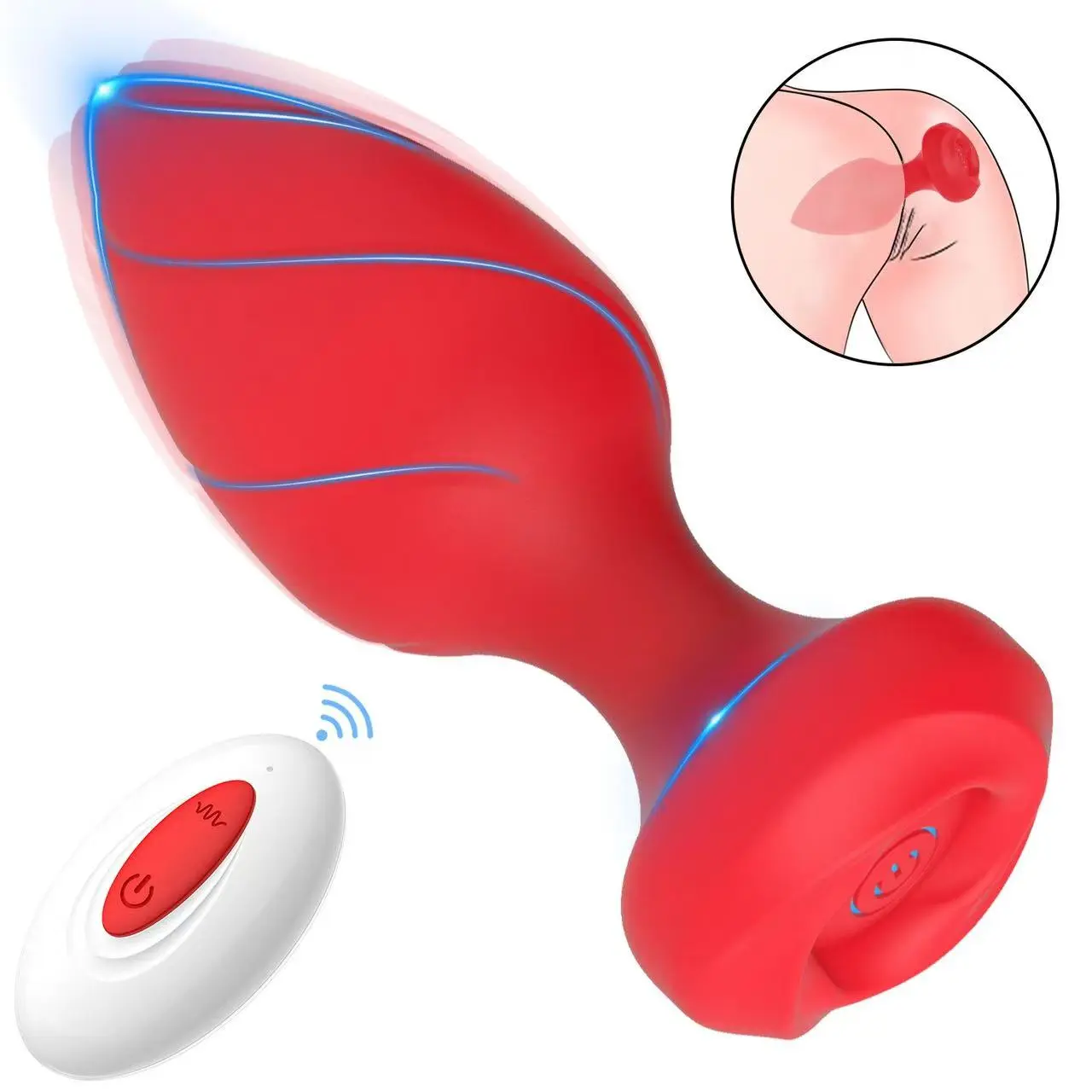

As a leading wholesale silicone tail plug manufacturer, I take pride in offering high-quality products tailored to your needs. Our silicone Tail Plugs are designed for comfort and durability, making them ideal for a wide range of applications. With a focus on ODM services, we work closely with our clients to ensure that each product meets their specific requirements, I understand that finding reliable suppliers can be a challenge, which is why we prioritize quality and customer satisfaction. Our expertise in manufacturing means we can produce unique designs and variations that align with your brand, Whether you're looking to stock your retail store or expand your product line, we have the solutions you need. Partner with us for competitive pricing, fast turnaround times, and exceptional service. Let’s create something amazing together!

Key Methods For Wholesale Silicone Tail Plug Manufacturer Your End-to-End Solution Application

When it comes to sourcing high-quality silicone tail plugs, finding a reliable wholesale manufacturer is crucial for your business's success. At 9sexy, we specialize in providing a comprehensive end-to-end solution tailored for the sexual wellness industry. Our commitment to excellence ensures that our customers receive not only top-notch products but also outstanding support throughout the procurement process. Understanding the unique demands of the sexual wellness market, we prioritize innovation and quality in our silicone tail plug offerings. Our extensive selection is designed to meet diverse preferences, ensuring your inventory remains appealing to a broad customer base. With competitive pricing and a commitment to customer satisfaction, partnering with 9sexy means you can focus on growing your business, knowing that you have a dedicated manufacturer by your side. Furthermore, our exceptional customer service sets us apart from other wholesalers. From the initial inquiry to post-purchase support, our experienced team is here to Assist you every step of the way. We believe that a successful partnership is built on trust and communication, which is why we strive to provide timely responses and solutions tailored to your needs. Choose 9sexy as your wholesale silicone tail plug manufacturer and experience the ease of a seamless sourcing journey.

Key Methods For Wholesale Silicone Tail Plug Manufacturer Your End-to-End Solution Application

| Method | Description | Benefits | Application |

|---|---|---|---|

| Injection Molding | A method where silicone is injected into a mold under high pressure. | High precision and efficient production with minimal waste. | Used for high volume production of tail plugs. |

| Compression Molding | Silicone is placed into a heated mold where it is compressed and heated to cure. | Cost-effective for lower volume runs and large parts. | Ideal for custom or special order tail plugs. |

| Liquid Silicone Rubber (LSR) Molding | Using liquid silicone in a two-component system that is mixed and injected into a mold. | Offers excellent thermal stability and flexibility. | Suitable for intricate designs and complex shapes. |

| 3D Printing | Additive manufacturing technique to create silicone parts layer by layer. | Fast prototyping and customization. | Used for producing unique or bespoke tail plug designs. |

Why Wholesale Silicone Tail Plug Manufacturer From Concept to Delivery Exceeds Industry Benchmarks

W

William Adams

I was blown away by the quality of this item. The after-sales team provided exceptional support throughout the process.

21 May 2025

S

Sofia Bell

An exceptional product! The quality is remarkable, and the customer service representatives were so helpful.

24 May 2025

H

Hannah Johnson

Outstanding quality! The customer service team provided knowledgeable assistance without delay.

03 June 2025

S

Samantha Scott

Absolutely love the quality! The support staff was knowledgeable and ready to assist.

25 June 2025

Z

Zoe Lewis

Very impressed with the quality! The service staff was professional and really knew their product.

04 July 2025

I

Isabella Wright

This product exceeded my expectations! The service team was knowledgeable and attentive.

29 May 2025